How To Install A Prefab Shower Stall

How to Fit a Shower Tray

Learn the key steps for how to set up a solid base of operations and run a trouble-free drain

![]() Fourth dimension

Fourth dimension

Multiple Days

![]() Complication

Complication

Intermediate

![]() Cost

Cost

$101–250

Introduction

Preformed, jumpsuit shower bases make installing a new shower much easier. This article explains the process, from ripping out the former shower or tub to how to install the shower pan and the plumbing.

Tools Required

Materials Required

- 1-1/two-in. P-trap

- one-1/2-in. pipe and elbows for waste matter and vent

- ane/ii-in. copper or CPVC supply lines

- one/2-in. plywood

- 2 x 4s

- 2-in. screws

- 2-in. 10 1-i/2-in. reducer coupling

- Mortar mix

- Shims

- Shower base of operations

- Transition couplings

- washers

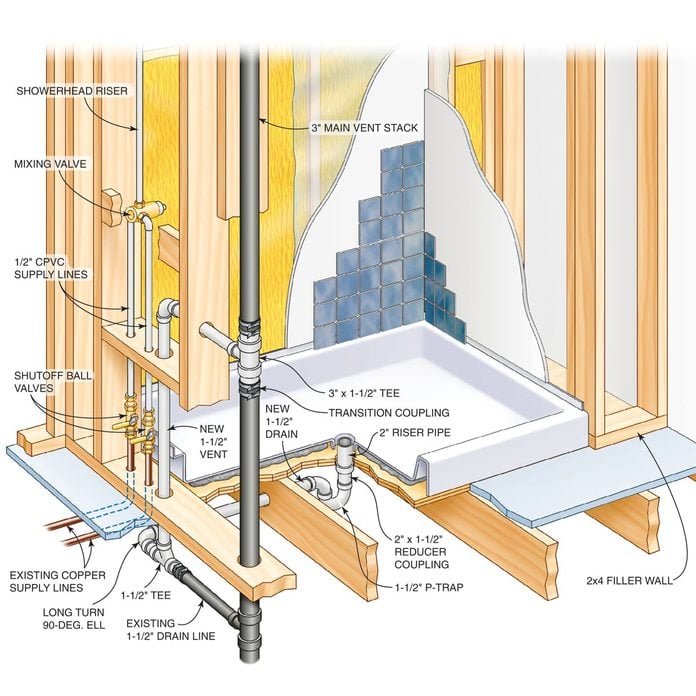

How to Fit a Shower Tray Overview

Permit's face up information technology. Showers are the bathing choice of simply about everyone. So if your bathroom has go a family unit bottleneck because you don't have plenty shower stalls or the one yous accept is leaking, read on. Nosotros'll show you how to replace a leaky base (aka shower tray or shower pan), replace a tub with a shower only or install an additional shower to handle demand. Preformed shower bases have vastly simplified the installation process. They're virtually leakproof and are vastly easier to install than traditional solid mortar bases.

Still, setting a base of operations can be challenging, particularly when you're remodeling older plumbing. In this article, nosotros'll prove yous how to rip out an old tub and supplant information technology with a i-slice fiberglass shower base. We'll walk you lot through the tricky parts, beginning how to relocate the drain merely correct, then the necessary venting. Next, we'll show how to set up a rock-solid base—one that won't crack or leak down the route. Our footstep-by-step instructions will take you right up to the point where the walls are ready to terminate. Only we won't go into those finish details hither.

This is mostly a plumbing project. To accept it on, you should be familiar with bones pipe joining techniques. Mostly this involves cutting and cementing plastic pipes and fittings. Don't worry if y'all brand mistakes. The materials are inexpensive and corrections are easily fabricated by cutting out sections and installing new fittings and pipes.

Completing this task—getting the erstwhile tub out, reworking the plumbing and installing the new base—will take a Sabbatum at to the lowest degree, a weekend at well-nigh. If you have to run a bleed line through joists or studs, we recommend that you rent a 1/2-in. right-angle drill and a 2-in. hole saw (or bit). Otherwise, basic plumbing tools and hand tools are all you'll demand. Be sure to employ for a plumbing let and take an inspection done at the crude-in phase (when everything is still exposed) and after everything is complete (wall surfaces finished, concluding hardware installed).

Projection step-past-pace (19)

Step 1

Planning the Task

Start past deciding on the size of the shower base and ordering information technology. Delivery can take weeks, so don't rip anything apart until the new one is in hand. If you're replacing an existing base of operations, just go one the same size. If y'all're replacing a tub with a shower as nosotros did, there are more than details to consider. You'll have the fewest problems if y'all match the new base to the old tub'southward width (the front of the tub to the wall). Go wider if you like, only yous may have to replace flooring. Or you may overstep required minimum distances from toilets and sinks. You lot might have to shift the supply valve too. Keeping the same tub footprint (or smaller) minimizes the hassles.

We replaced a 5-ft. tub with a adequately spacious iv-ft. base the same width as the tub. We framed a one-ft.-wide filler wall at the end, which is a dainty identify to build recessed niches and shelves for shower supplies.

At present's a adept time to buy a new shower valve too, specially if your onetime one doesn't have scald protection, as all new ones practise. It'due south a big project to replace a valve that fails after tile or wall panels are installed.

Yous'll need an assortment of pipes and fittings for installing the new drain and for reworking h2o lines. Choice them upward afterward you lot open up the floor and walls. At that point, you tin can see what you need, plan the new bleed and water supply runs and make a list of supplies. Brand a sketch like Effigy A to assist y'all keep track of parts.

Pace 2

Shower Base/Drain Details

Make a sketch of the projection that includes the waste, vent and water supply. Drawing the details will help avoid potential problems and besides reduce the number of trips to the hardware shop.

Information technology's also important to notation that you lot won't be able to enter a dwelling center and walk out with a 4-ft.-long shower base like the i we show in this project. Inquire to get through the plumbing fixture books in that location to special-guild i that suits your bath decor and budget. Some come with bleed adapters, equally ours did. You lot'll have to check and purchase a separate shower drain kit if needed. The manufacturer'due south directions will help you lot choose the right one.

At that place is another (simply more costly) selection if you'd like to skip all of the actress venting and drain work. Select a shower base that has the drain located at ane end, right or left, chosen to lucifer your one-time tub bleed. Select 1 the same length as the tub and you won't even need to add filler walls. Since the drain position roughly matches the tub drain, you may not have to add a dissever vent, cut out and patch the floor, or reroute the drain line.

Step iii

Remove the Wall

First, unscrew the showerhead and the bathtub spout. Nearly styles will unscrew, but some will need persuasion with a pipe wrench. If you want to reuse whatsoever parts, wrap the tool jaws with a cloth to prevent damage. Then remove the handle and mixing valve escutcheon cover. Most handles have a fiddling plastic cap that pops off to expose a screw. Remove the screws and pull off the handle and the escutcheon.

Next, strip off the tub surroundings. Brainstorm past cutting completely through the drywall around the perimeter with a utility knife. If you lot accept cement board behind the tile, but cutting through the tape joint at the ceiling and strip the entire wall. Rip off the tile and drywall together in big chunks. If you have a fiberglass environs with a flange behind the drywall, cut two in. outside of the enclosure and pry the sections gratuitous one at a fourth dimension.

Pace 4

Disconnect the Plumbing

With the wall open, disconnect the plumbing and shut off the main h2o supply valve. Unremarkably, y'all can access the trap from an access console in the room backside the tub or from an unfinished basement. If you don't have admission, you'll have to cut a pigsty in the wall from behind the tub base of operations. If your shutoff valves are in good shape, cut off the water lines above them. If they're missing, stuck or corroded, shut off the master supply valve, cut off the water lines and install two compression plumbing fixtures–style ball valves and exit them in the closed position so you lot can plow the h2o back on to the rest of the house. Encompass the ends with tape to keep out debris.

Step 5

Remove the Tub

Disconnect the trap from the tub drain, then elevator the tub free from the wall. Fiberglass and steel tubs are fairly low-cal, then you can simply tip them up and carry them abroad. If framing makes information technology difficult to pull out, cut out more drywall along the plumbing wall. Then you tin pull the tub away from the wall before yous tip it up. Bandage iron tubs, on the other paw, are extremely heavy, and we recommend just busting them upwards with a sledgehammer and carrying out the pieces. (Lay an former coating over the tub to grab flying shards, and vesture rubber spectacles for this!)

Acquire which tools are best for breaking upwards a cast iron tub.

Step 6

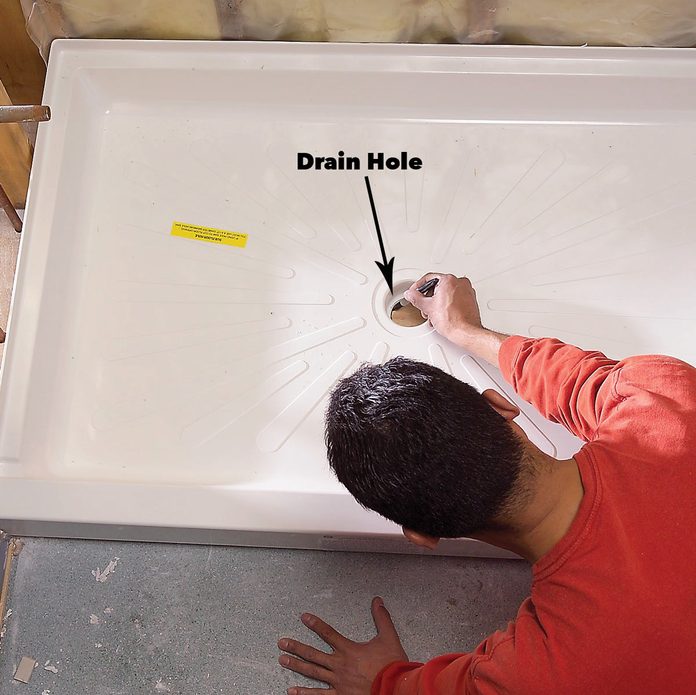

Marker the New Drain

Snug the new shower base upward to the wall studs and mark the drain pigsty.

Step 7

Cut an Access Slot

Cutting an Access Slot

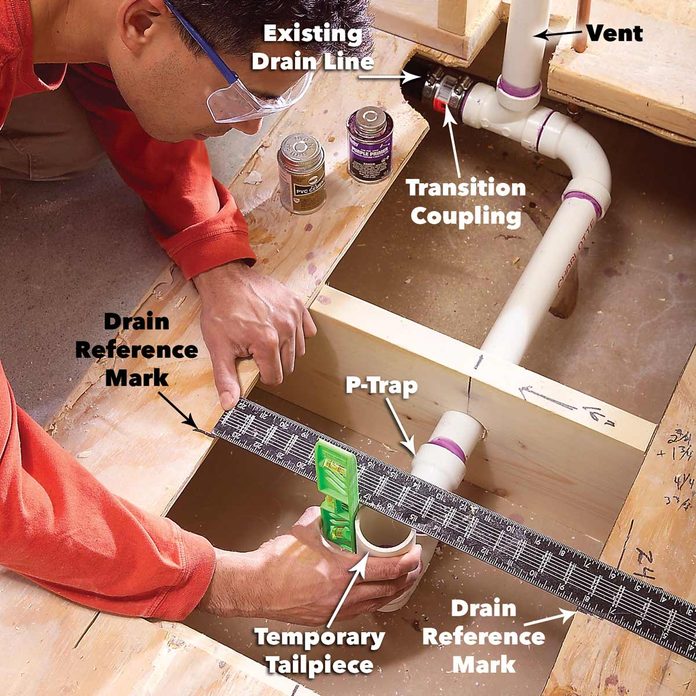

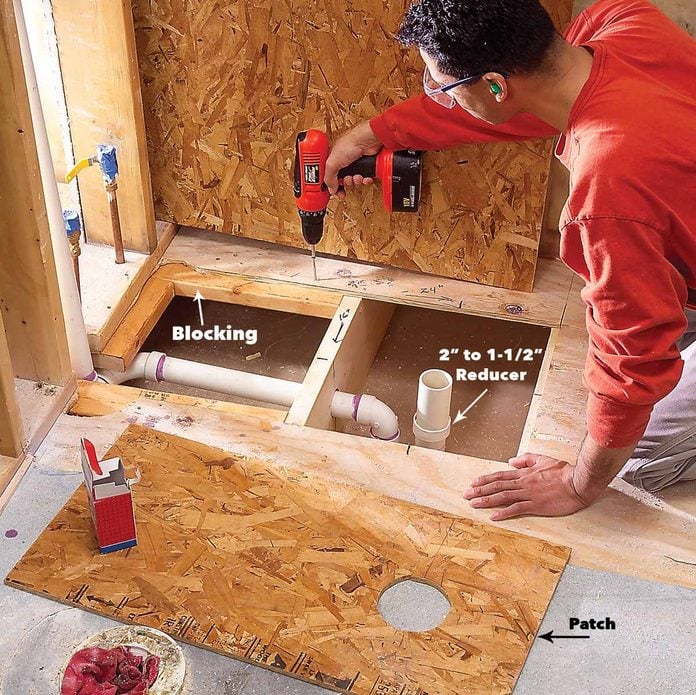

Put the new shower base of operations aside and draw an access slot on the subfloor, roughing in the new P-trap and bleed line. Brand the slot about a pes broad and extend it only beyond the new bleed location. Keep the edges of the slot over the heart of the joists wherever you tin can to make patching easier later. Pull whatsoever nails that fall inside the cutting lines. Then ready your bract depth to cut just through the subfloor, make the cut and pry information technology free. Exist sure to make reference marks on the floor outside the slot so y'all can relocate the heart of the drain in one case you lot remove the floor.

Footstep viii

Cut a Path for the Drain

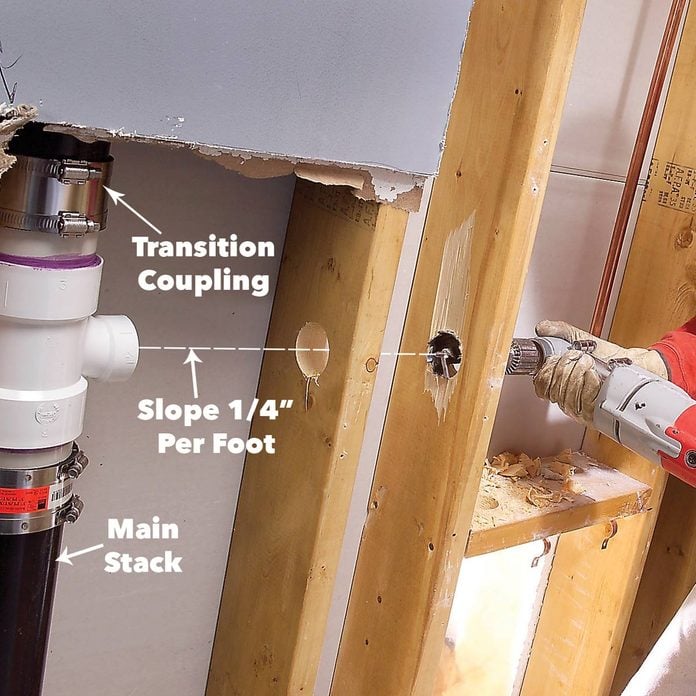

With the flooring and wall open, you tin can plan your new drain and vent lines. Reworking bleed and vent lines will be slightly different with every bath, just our photos and Figure A will give y'all the general thought along with a look at the diverse fittings you may need.

The two keys for adding a drain are to make sure the horizontal lines slope 1/4 in. for every running foot and that the P-trap opening falls straight below the shower drain hole. Start by measuring the peak of the middle of the existing drain line and the altitude to the new drain. Cutting off the onetime P-trap, and then run the drain line to the new drain location. Drill 2-in. holes through the floor joists for the new drain line. Reference marks help you find the drain middle afterwards.

Call back to let 1/4-in.-per-foot gradient when you drill holes in joists. Drill two-in. holes to leave some room to motion the 1-1/2-in. piping up or downwards to go the necessary gradient. But don't drill in the lower or upper two in. of any joist. Well-nigh shower drains are designed to receive two-in. piping, while almost existing tub drains are 1-1/2 in. The plumbing lawmaking calls for the transition to be made with a reducer directly below the shower, nowhere else.

Pace 9

Install the Sanitary Tee

To run the new vent, mark a section of main stack for removal using the 3 x one-1/2-in. tee (with 6-in.- long nipples) as a guide. Cement 6-in.-long nipples to both ends of a 3 x 1-1/2-in. sanitary tee, then marking and cut the main stack. Join it to the stack with transition couplings.

Step 10

Run the Vent

If your tub didn't have a vent, you'll probably take to add ane. A local plumbing inspector will tell you the rules (usually inside 42 in. of the shower P-trap) when you apply for a permit. The new vent must bring together the main vent at least vi in. above any "spill lines" (that usually means sink rims) that share the vent. If your main stack volition be plastic, cutting it is easy with a hand or reciprocating saw with an viii-in. blade. If you have bandage iron, you lot'll have to rent a pipage snapper to make the cut.

Run the vent line down to the drain by drilling two-in. holes through the studs, sloping away from the tee 1/iv in. for every ane ft. of run.

Stride 11

Dry-Fit the Waste and Vent

Cutting all the pipes and dry-fit the new vent line and drain line fittings one at a time, working your fashion toward the P-trap. Begin cementing the parts together. If yous're using PVC, hold the parts together for most 20 seconds afterwards cementing. Otherwise, the parts will "squirt" apart earlier the solvent cures. Save the P-trap-to-drain-line connection for last. Cement information technology together, and quickly plumb the P-trap with a vi-in. level before the joint sets.

Use reference marks on the subfloor to fine-tune the location of the drain. Set the shower base in place to double-check the final placement of the P-trap, inserting a short, temporary tailpiece. When you lot set the shower base permanently, measure and cut a permanent tailpiece and cement information technology into place. Your building inspector will desire to run across the drain and vent (and possibly the water supply rough-in) before yous close up the floor.

Stride 12

Shut the Flooring

Add blocking to bolster unsupported plywood edges and screw a patch to the framing with 1-5/8-in. screws. We added a second layer of 1/ii-in. underlayment nether the entire shower for a sturdier flooring and to better match the finished floor height (1/2-in. backer board and tile). If you need to preserve the original floor height, skip the second layer, but add blocking under the single-layer patch to fully support the shower base.

Step 13

Mount the Mixing Valve and Redo the Supply Lines

Unless you lot're planning to reuse all of the existing supply lines and valves, simply cutting out and remove everything and starting time fresh. Use a hacksaw or a reciprocating saw.

If you've chosen a shower base that's wider than the tub, center the new mixing valve and showerhead over the base. Cull a valve height that'due south comfortable to accomplish and clears whatsoever obstacles, and make sure the showerhead lands either above or below the acme border of the shower enclosure or tile. Mountain the mixing valve get-go, post-obit the manufacturer's instructions, and run new CPVC or copper tubing from the ball valve to the mixing valve and showerhead. Cap the tub spout outlet on the underside of the mixing valve. Yous'll need to add blocking to support it.

At that place may exist a threaded nipple or pigsty in the bottom of the mixing valve for a tub spout. Exist sure to cap that. After everything is together, shut off the mixing valve, turn on the h2o and check for leaks.

Stride 14

Level the Base and Mark the Studs

Level the shower base on all four edges, shimming where needed. Mark the lip where it abuts studs. Mensurate, cutting and cement the terminal tailpiece to the P-trap. Take your time. Getting the base level is disquisitional for good drainage. Mark the lip height on the studs and outline the shim locations so you can elevator out the base of operations and return it to the exact position. Some bases crave that you fit it over a tailpiece when you ready it in the mortar.

Step xv

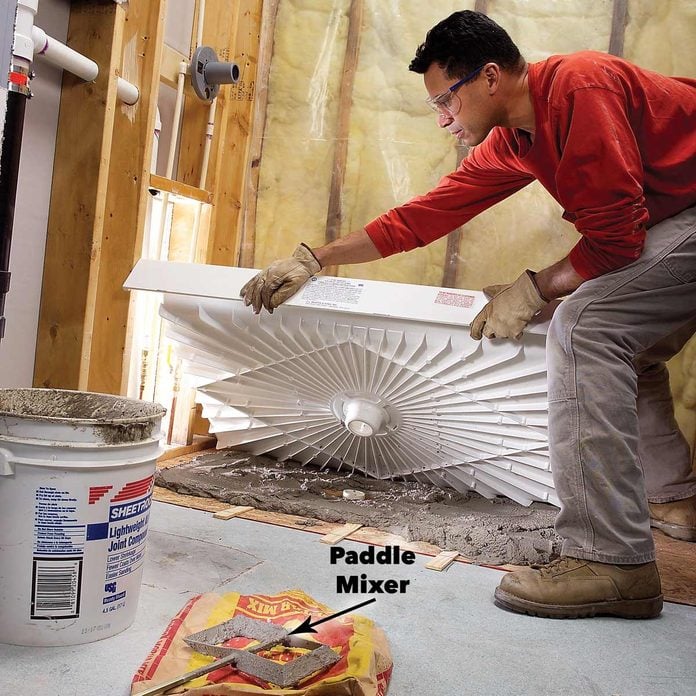

Ready the Base in Mortar

To fix the base, mix up about half a threescore-lb. bag of mortar with water to a creamy consistency. Avoid concrete mix; stones in the mix volition concord the base away from the floor. Spread the mortar over the floor nether the base, about one in. or so thick. Then lower the base into the moisture mix, forcing it down to the shims and the stud marks. Make certain to push button information technology confronting the wall. Let it cure overnight. Don't use the base of operations as a work platform until the next day or you'll disturb the mortar before it cures. Clamp the base lip to each stud if clamps are included with the unit. Otherwise, clamp information technology with fender washers and 2-in. screws. Avoid drilling through the lip and screwing the base direct to the studs. The base might crack and leak.

Step 16

Complete the Drain Hookup

The new shower stall base will have directions to guide yous through the final drain hookup; your bleed system may vary from ours. Just our shower stall bases directions were to anchor the base of operations to the studs with screws and washers and so push button the rubber gasket into identify and seat it with a nut driver. Basic directions for how to complete the drain hookup for the new shower stall base of operations are to cut the tailpiece and cement it at the correct summit. If your drain has a thick rubber gasket, wet information technology with soapy h2o and so work it effectually the tailpiece pipe. Finish seating it past driving it downwards with a blunt tool.

Footstep 17

Drain Cover

Adhere the bleed cover to the drain opening.

Footstep 18

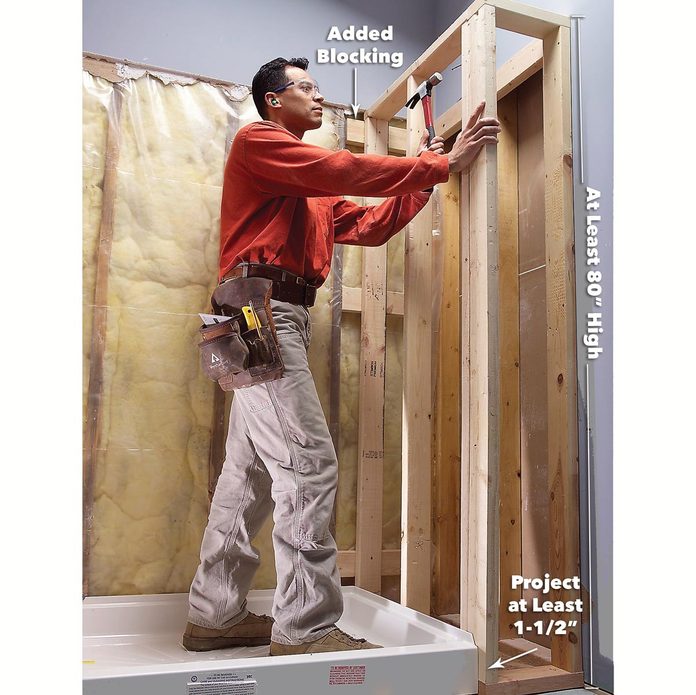

Consummate Shower Framing

Frame the finish wall at least 80 in. high for shower doors and curtain rods. Additionally, our base was shorter than the old tub, leaving a void between the wall and the base. We filled in the space with a 2x4 wall. Add backing where the new walls see existing ones to brand the connexion solid and for anchoring backer board. And if you lot exit information technology short of the ceiling equally we did, yous can add a convenient built-in shelf.

Step 19

Copper vs. CPVC

If you lot're comfortable working with and soldering copper, by all means, go ahead and use it for your water supply lines. We evidence CPVC plastic fittings considering the installation is as uncomplicated equally cutting and cementing plastic fittings, just as you exercise with plastic drain and vent lines. To make the transition from copper to CPVC, utilise compression fittings as shown. Y'all'll find all the CPVC fittings and pipes you need at any hardware shop or dwelling eye.

Check out the pros and cons of thicker and thinner copper pipe.

Originally Published: December 03, 2022

Source: https://www.familyhandyman.com/project/plumb-install-a-shower-base/

Posted by: rothrockfromork.blogspot.com

0 Response to "How To Install A Prefab Shower Stall"

Post a Comment